Which Of The Following Is A Traditional Logistics Customer Service Metric?

KPI Examples for the Logistics Manufacture

Logistics Key Performance Indicators and Metrics

✔ Run into different templates & designs ✔ Find & runway the right logistics KPIs to meet your corporate objectives

A logistics KPI or metric is a performance measurement that is used by logistics managers to track, visualize and optimize all relevant logistic processes in an efficient way. Among others, these measurements refer to transportation, warehouse and supply chain aspects.

The logistics industry produces huge amounts of data on a daily footing coming from warehousing processes, orders transportation, picking and packing, among others. That said, companies who do good from logistics analytics solutions to amend their performance are the ones that will thrive in the long run. To aid you accomplish this type of success, nosotros put together a listing of professional logistics metrics that will non only ensure that your business operational processes are running smoothly, just will help yous optimize costs while still maintaining a quality service. If you want to extract deeper insights from these metrics, put them together in a logistics dashboard with the help of a professional dashboard tool and accept advantage of powerful data visualizations.

Here is the consummate list of the most important logistics KPIs and metrics, that we will discuss in this article in every particular:

Shipping Fourth dimension: Spot potential issues in your order fulfilment process

Club Accuracy: Monitor the degree of incidents

Picking Accuracy: How many orders are picked without errors?

Delivery Time: Runway your boilerplate delivery time in particular

Pick & Pack Cycle Time: Track the time information technology takes to selection and pack your orders

Equipment Utilization Charge per unit: Is your equipment enough for your workforce?

Transportation Costs: Analyze all costs from the guild placement to commitment

Warehousing Costs: Optimize the expenses of your warehouse

Pick & Pack Costs: Monitor all costs related to your pick & pack process

Use of Packing Material: Optimize your materials usage

Number of Shipments: Understand how many orders are shipped

Inventory Accuracy: Avoid problems because of inaccurate inventory

Inventory Turnover: Track how many times your entire inventory is sold

Inventory to Sales Ratio: Identify a potential overstock

Shipping Fourth dimension

Spot potential issues in your society fulfilment procedure

The On-Time Shipping performance refers to the ratio of orders that have been shipped on or before the requested ship date divided by the full number of orders. This is a first logistics KPI to help you lot measure your supply chain functioning. Indeed, if the amount of fourth dimension between the moment the customer placed his order and the moment that order is prepared to be shipped is too long, that tin show some trouble in the process that need to be fixed. Whether information technology is outdated planning processes or disconnected execution systems too slow to face an increasing demand, the issues need to be addressed to quickly answer unexpected events.

Operation Indicators

Later realizing a benchmark of the boilerplate time you lot need to ship a certain blazon of gild, you tin can set a target shipping time relative to each product to accomplish.

Relevant Showcase Dashboard

- Warehouse KPI Dashboard

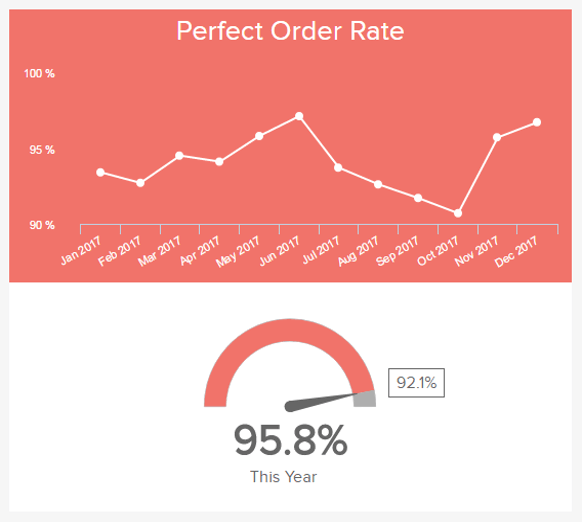

Society Accuracy

Monitor the degree of incidents in your warehouse

The Perfect Club Rate is another highly of import logistics metric when information technology comes to your supply chain efficiency. It measures the amount of orders that are processed, shipped and delivered without any incidents on its fashion. The shipping time as well as the delivery fourth dimension are both respected, the order is not a wrong one and the goods are not damaged. It is important as it shows the efficiency of your supply chain and commitment services, and that leads of course to more satisfied clients that are willing to come back or recommend your services.

Performance Indicators

The higher is this rate, the ameliorate it is for your business concern. You lot will lose less money with returns of inaccurate or damaged goods, and increment the level of satisfaction of your client base of operations.

Relevant Showcase Dashboard

- Warehouse KPI Dashboard

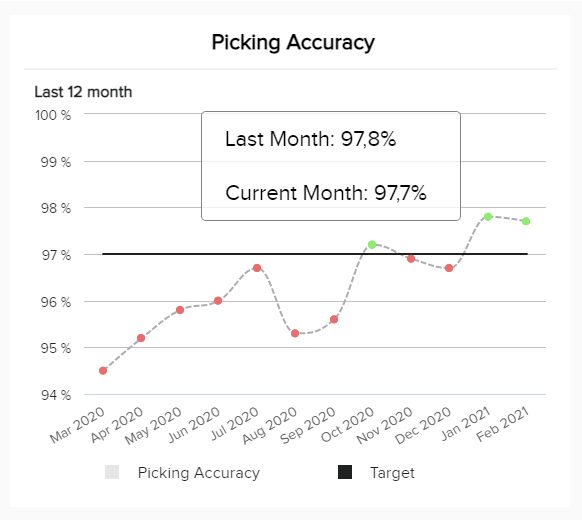

PICKING ACCURACY

How many orders are picked without errors?

The picking accuracy is another warehouse KPI related to the quality of your pick & pack procedure. The aim of this metric is to rail the pct of orders picked without errors from your total number of orders, and it is calculated with this simple formula: (Total orders – Returns due Incorrect Particular) / (Total orders). This metric directly affects customer satisfaction levels since it ensures customers will receive the correct item from their order. Additionally, a higher picking accuracy will save significant costs on relocating wrong shipped items, therefore companies should brand sure to monitor it constantly.

Operation Indicators

Measure out the picking accuracy based on your returned products only as well do random checks of picks to ensure no mistakes are fabricated.

Relevant Showcase Dashboard

- Pick & Pack Scorecard

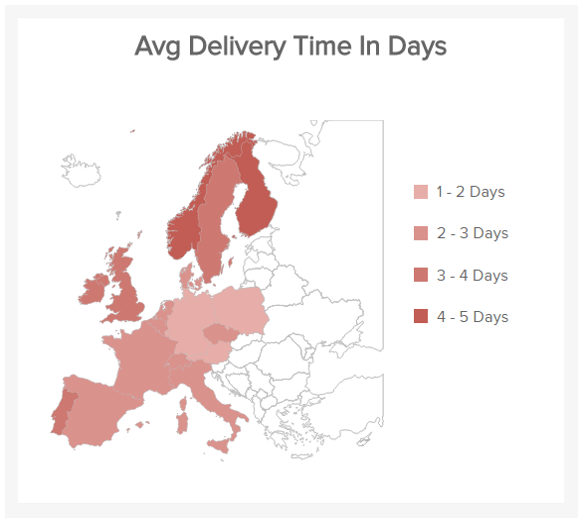

Delivery Time

Track your average commitment fourth dimension in detail

The Boilerplate Time Commitment is measured from the moment the social club is placed to be shipped and the moment it is delivered to the customer/post office. Afterwards benchmarking and having an idea of the boilerplate delivery time from your warehouse to anywhere, the goal would be to decrease it when possible - offering special delivery services for instance - only more importantly, to precise it. Saying that an lodge will make it in four-five business days is improve than saying information technology will arrive in one-to-5 business organisation days. Additionally, if you can precise the commitment hours (between 13h and 15h rather than between 8h and 18h), it is even better. That mode, your customer knows when he should be home to pick the packet up, increasing your order picking accurateness rate and avoiding returns.

Performance Indicators

This is a typical logistics KPI example to narrow down and precise as much every bit possible for a amend service.

Relevant Showcase Dashboard

- Transportation Dashboard

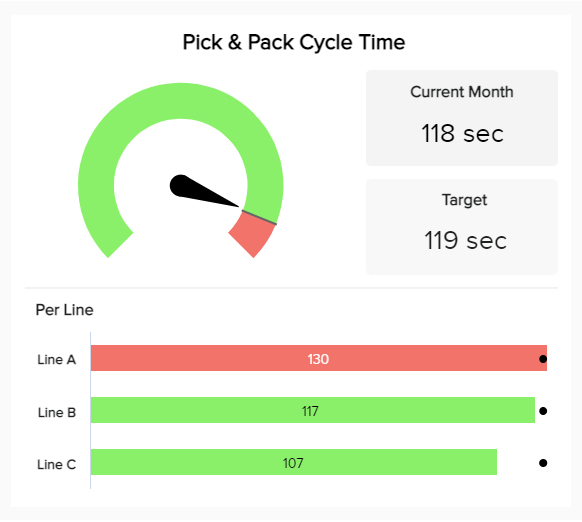

Pick & Pack Bike Time

Is your pick and pack cycle efficient?

The choice & pack cycle time is a logistic KPI that tracks the amount of fourth dimension it takes an employee to pick an detail from a shelf to the fourth dimension the packing process is done. This metric is calculated past dividing the total amount of time with the total number of items picked and packed in a set menstruum. In the example, we meet that the operation of each line is being tracked based on a target, and that line A is a bit higher up it. This is valuable information equally it allows you to have a deeper look into the procedure of that line and detect out what could be delaying the pick and pack. Measuring each line of piece of work separately too enables y'all to endeavor different strategies for each of them and see which one is the virtually effective.

Performance Indicators

Ready realistic targets to track your choice and pack cycle time based on your total number of orders and the workforce available.

Relevant Showcase Dashboard

- Pick & Pack Scorecard

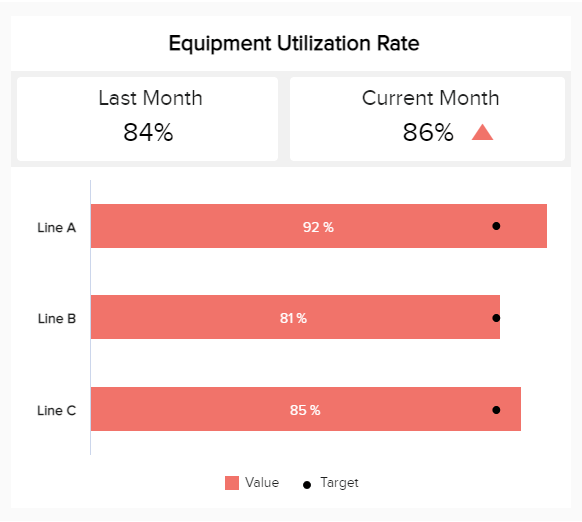

EQUIPMENT UTILIZATION Charge per unit

Is your equipment plenty for your workforce?

Next in our list of logistics metrics examples comes the equipment utilization charge per unit. Although employees are the ones doing the heavy piece of work, engineering and equipment are a fundamental aspect for the efficiency of any warehouse procedure. The prototype in a higher place displays a percentage of the equipment usage in each line of work based on a target of last month's performance. In this case nosotros can see that lines A, and B are over the target and that C is at the limit, this could mean that an investment in more equipment might be needed to improve functioning in this area.

Functioning Indicators

A healthy equipment utilization rate should exist between 70-90% as this ensures that your employees are not waiting in line to utilise the equipment.

Relevant Showcase Dashboard

- Pick & Pack Scorecard

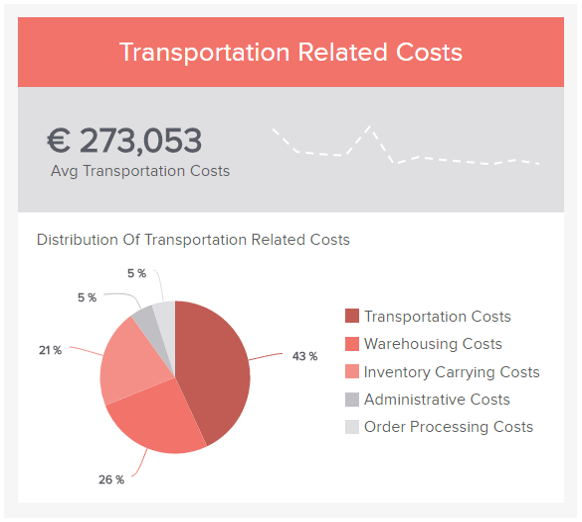

Transportation Costs

Track costs from the order placement to its delivery

The Boilerplate Transportation Costs calculates an overall of the expenses involved in processing an order from the commencement to the end. It will pause down all the costs related to this logistics KPI according to distinct categories: the order processing, the administrative, the inventory carrying, the warehousing and finally the bodily transportation costs. Later calculating all these, you tin evaluate the per centum each stage of the process represents and meet if that is excessive or in the norms. You can likewise calculate the transportation costs relatively to a product and see how much one detail costs compared to how much revenue it brings y'all.

Performance Indicators

The goal is to decrease the transportation costs while maintaining a high quality of delivery.

Relevant Showcase Dashboard

- Transportation Dashboard

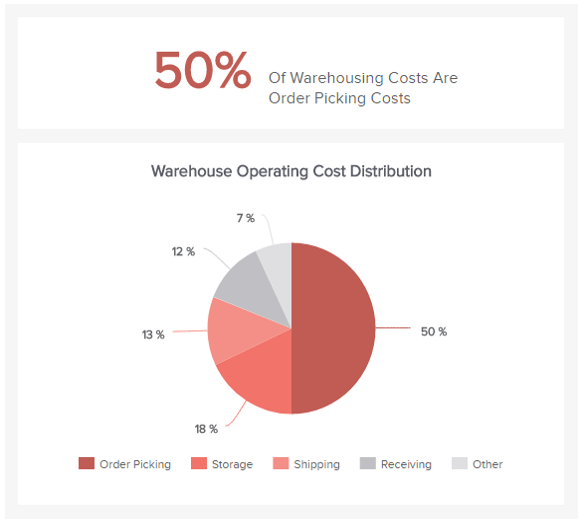

Warehousing Costs

Monitor the expenses of managing your warehouse

Warehousing is the management of space and time. The Warehousing Costs refer to the money allocated to the appurtenances moved into or outside the warehouse. These expenses comprehend equipment and energy costs like ordering, storing and loading the goods, besides as more human costs like labor, shipment, or delivery. The warehousing costs are a component of some other logistics KPI, the total transportation costs. Measuring them is non an piece of cake task, but one time it is washed it will facilitate your overall direction and add a lot of value, something that senior management or investors volition appreciate.

Performance Indicators

Warehouse existence the master area of your business, it is of import to measure out and review the costs on a regular footing, so as to meliorate your operations and evaluate such improvement.

Relevant Showcase Dashboard

- Warehouse KPI Dashboard

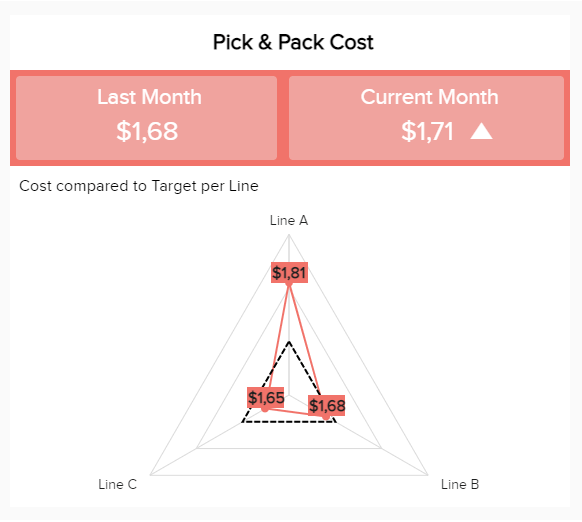

Pick & Pack Costs

Monitor all costs related to choice & option processes

Our side by side logistic KPI example is the pick & pack costs. This metric aims to measure all cost aspects related to the picking and packing of your orders. For example, the workforce, the packaging materials, or equipment. Your last goal here should be to ever keep the costs equally low as possible. Therefore, monitoring this KPI will exist useful to empathize if you are spending more than resource than needed in the entire process. The pick & pack costs can too be analyzed deeper past dividing it into products or production categories, this way you lot can see exactly where your costs are going upwards and detect productive solutions for information technology.

Performance Indicators

An effective way to optimize your pick & pack costs is to test different picking and packing methods and techniques on each line of work and meet which i is more cost and time efficient for your business.

Relevant Showcase Dashboard

- Pick & Pack Scorecard

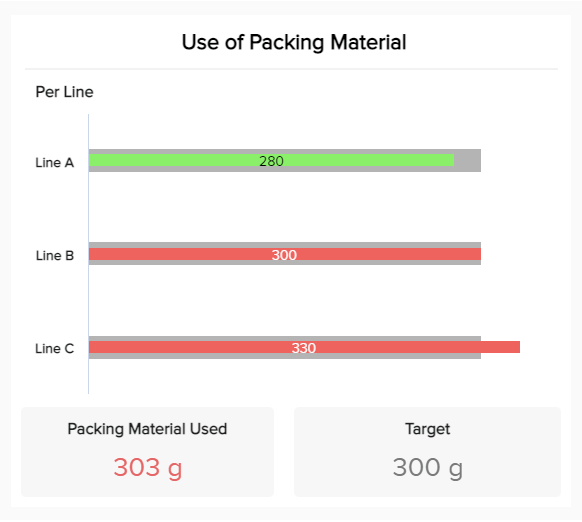

Utilise OF PACKAGING Cloth

Do you optimize your materials usage?

The use of packaging fabric is a warehouse KPI that aims to track the corporeality of materials used for packaging in each line of work in your pick & pack process. This is an important metric to rails since using more materials than needed can not only pb to higher costs merely also negatively impact the paradigm of your business for non adopting bones sustainable practices on your packaging. In the image above we see that line B and C are over the target of 300g of materials usage, this could hateful they are packing minor items in big boxes leading to a waste of resource.

Performance Indicators

In order to avert waste product of materials, set mandatory bundle dimensions related to the size of the item being packed this way you will save resources and keep your environmental impact to the minimum.

Relevant Showcase Dashboard

- Pick & Pack Scorecard

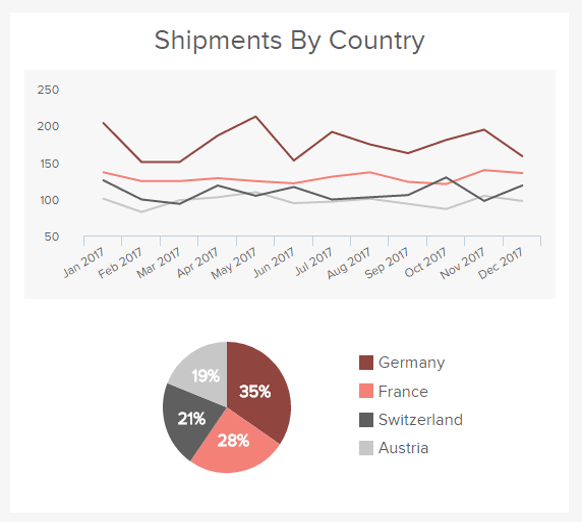

Number of Shipments

Monitor the orders shipped from your warehouse

Aircraft is not but a matter of dispatching appurtenances and packages in trucks or boats. Shipments are the showcase of your warehouse; their quality and the accuracy to chief order will demonstrate the quality of your service also. The same mode y'all measure the number of orders placed ready on time to be shipped (On-Fourth dimension Shipping KPI), you tin measure the number of orders shipped out of your warehouse. Analyzing the trends over time volition provide keen insights on rush hours or rush seasons (such equally Christmas time), and enable you to conceptualize and allocate more than resources accordingly.

Performance Indicators

Breaking downwardly this figure into several categories (countries, regions, types of products) will provide you greater data that you can use to optimize other logistics metrics, like the ones related to delivery.

Relevant Showcase Dashboard

- Warehouse KPI Dashboard

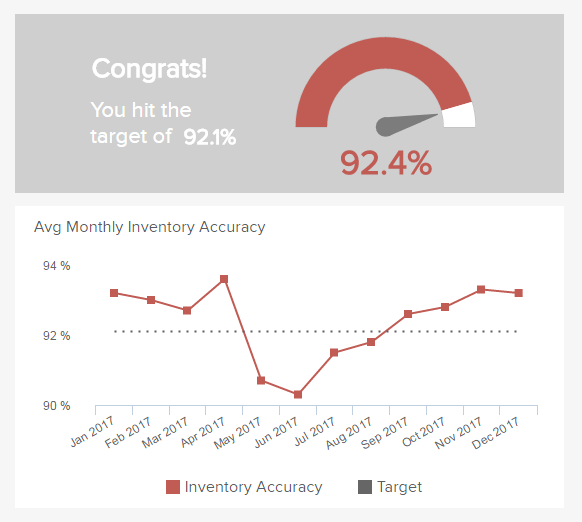

Inventory Accuracy

Avoid problems because of inaccurate inventory

Inventory Accuracy is one of those logistics metrics that can make or break your warehouse. Indeed, having a certain record of all your goods in your database that doesn't match the actual physical inventory tin damage your business considerably. If your inventory is inaccurate, that tin lead to unexpected backorders just also unsatisfied customers and more generally, college overall costs. A regular inventory checking the existing discrepancies with your electronic inventory record ensures that bookkeeping practices are in society and that your business is reliable, avoiding phantom inventory nightmares. This ratio volition also help you spot issues related to receiving, shipping, or accounting.

Performance Indicators

On a more realistic level, it is also normal to have some disparities between the record and the warehouse, only the idea is to maintain that ratio over 92% as much as possible.

Relevant Showcase Dashboard

- Supply Concatenation Dashboard

VISUALIZE AND TRACK YOUR LOGISTICS KPIS WITH A FEW CLICKS

Get a data wizard in less than i hour!

INVENTORY TURNOVER

Track how many times your entire inventory is sold

This logistics KPI measures the number of times your inventory entirely has been sold over a certain period of time. It is a great indicator of efficient production planning, procedure, also equally marketing and sales management. In general, the higher your turnover rate, the better. A low turnover may interpret difficulties in turning your stock into revenue, and that can come from any phase of your supply chain process. In that location is non one general rate to achieve, every bit it depends on the industry your company is evolving: a auto dealership will have a lower turnover than a common groceries store. The idea would exist to benchmark your manufacture average charge per unit and try to accomplish and exceed that target.

Functioning Indicators

After calculating yours, compare it to the average rate of your industry and surpass it.

Relevant Showcase Dashboard

- Supply Chain Dashboard

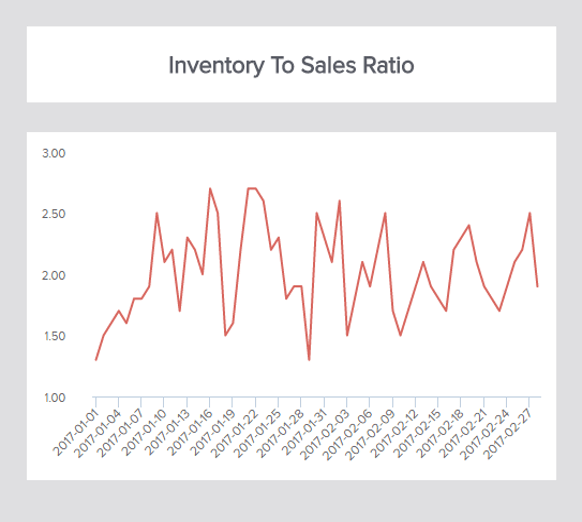

INVENTORY TO SALES RATIO

Evaluate how much inventory y'all deport in comparison to the number of sales performed

This logistics metric is adept at evaluating the overstock. It measures the ratio betwixt the available inventory for auction, versus the actual quantity that is sold. This is a cracking operation indicator that will besides tell you if your company is able to face unexpected situations. It is an even greater indicator if you measure and use it with other KPIs such as Inventory turnover, or the Carrying cost of inventory. That volition let you know about the fiscal stability of your business, only too the direction you desire to take - selling your inventory every bit quickly every bit possible or non.

Performance Indicators

Similar described above it really depends on your business concern what your target ratio should be. Usually you try to continue information technology not too high to avoid low inventory turnover rates.

Relevant Showcase Dashboard

- Supply Chain Dashboard

VISUALIZE AND TRACK ALL YOUR BUSINESS KPIS IN Ane Key Place

Setup only takes a few minutes. No credit card required!

Which Of The Following Is A Traditional Logistics Customer Service Metric?,

Source: https://www.datapine.com/kpi-examples-and-templates/logistics

Posted by: collinsarither.blogspot.com

0 Response to "Which Of The Following Is A Traditional Logistics Customer Service Metric?"

Post a Comment